Smart Gas Meter System Design Guide

Providing standardized smart gas meter remote reading system design, selection and implementation specifications for gas utilities, industrial parks and commercial buildings. Covering full lifecycle management from system architecture to construction acceptance, ensuring safety, accuracy and reliability of gas metering.

1.1 System Overview

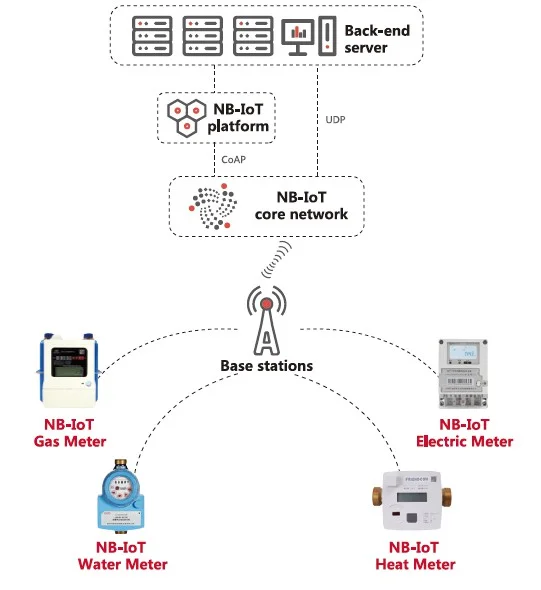

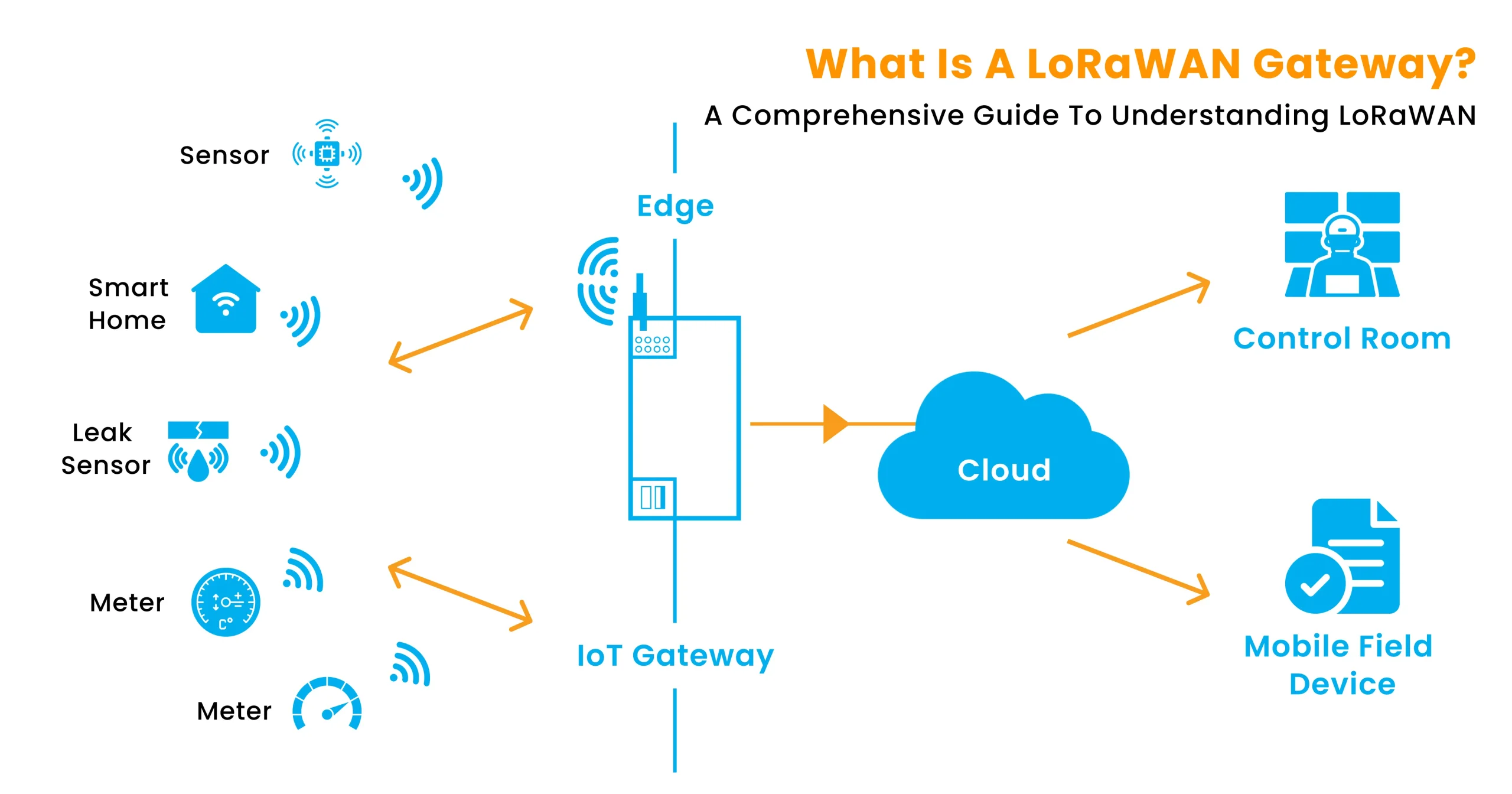

The Smart Gas Metering System is a comprehensive solution specifically designed for gas metering, aimed at achieving automated data collection, remote monitoring and safety management of gas meters. By integrating IoT communication technologies (NB-IoT, LoRaWAN, 4G/5G), ultrasonic/diaphragm metering technology and cloud data platforms, the system transforms traditional manual meter reading into intelligent remote monitoring and management. The system particularly emphasizes gas safety, supporting leak detection, remote valve control, and abnormal gas usage alarms.

1.2 System Architecture

The smart gas meter system adopts a layered architecture design to ensure high availability, security and scalability:

1.3 Key Features

Remote Meter Reading

Supports multiple communication protocols including NB-IoT and LoRaWAN for automatic data collection and remote transmission of gas meter data.

Safety Monitoring

Real-time monitoring of gas leaks, abnormal gas usage, and pipeline pressure, with support for remote emergency valve shut-off control.

Prepaid Management

Supports prepaid mode with automatic low balance alerts, automatic valve closure for arrears, and remote valve opening after recharge.

Data Analytics

Gas consumption statistical analysis, abnormal usage detection, leak early warning, energy consumption reports and predictive analysis.

1.4 Chapter Navigation

For quick navigation, chapter names are displayed as buttons. Below are the chapter link buttons:

System Components

Detailed introduction to the architecture, components and working principles of smart gas meter systems

1.1 System Architecture

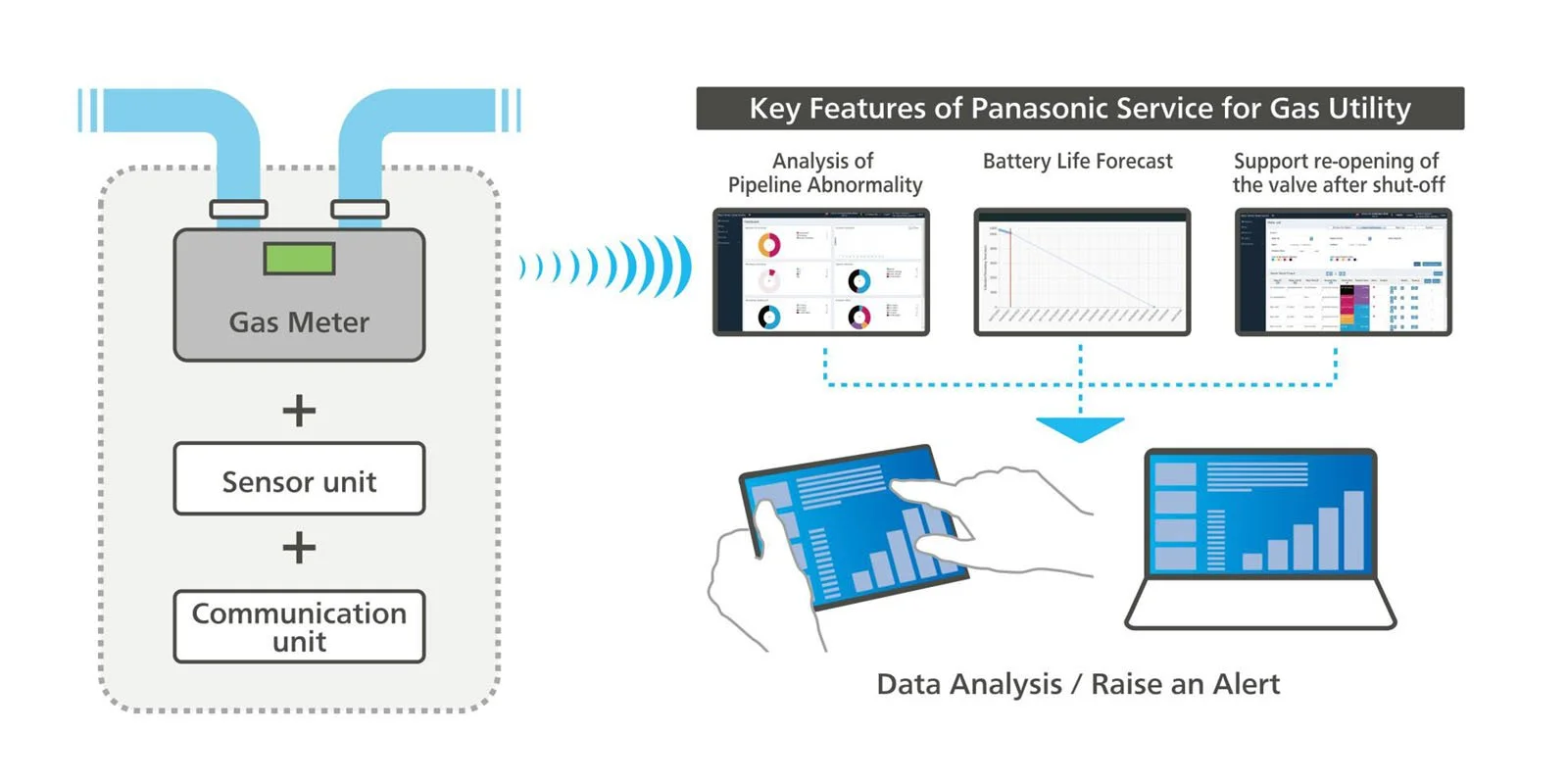

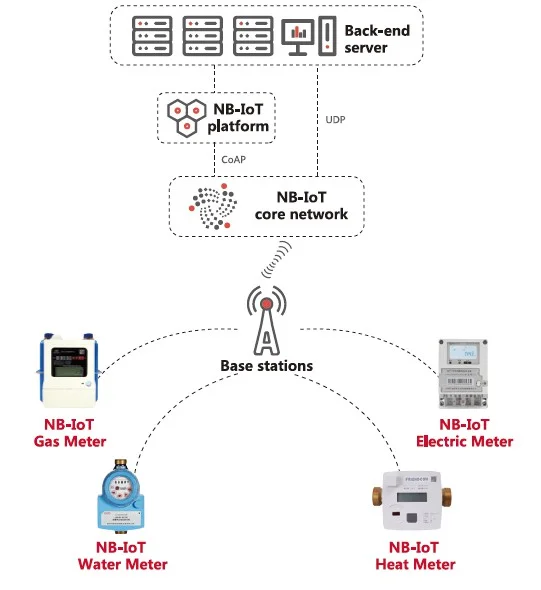

The smart gas meter system adopts Advanced Metering Infrastructure (AMI) architecture, which is an integrated, fixed network system that enables two-way communication between gas utilities and users. The architecture consists of four core layers: smart meter layer, communication network layer, data processing layer and application service layer. The system is specifically optimized for the safety requirements of the gas industry, supporting explosion-proof certified equipment and intrinsically safe circuits.

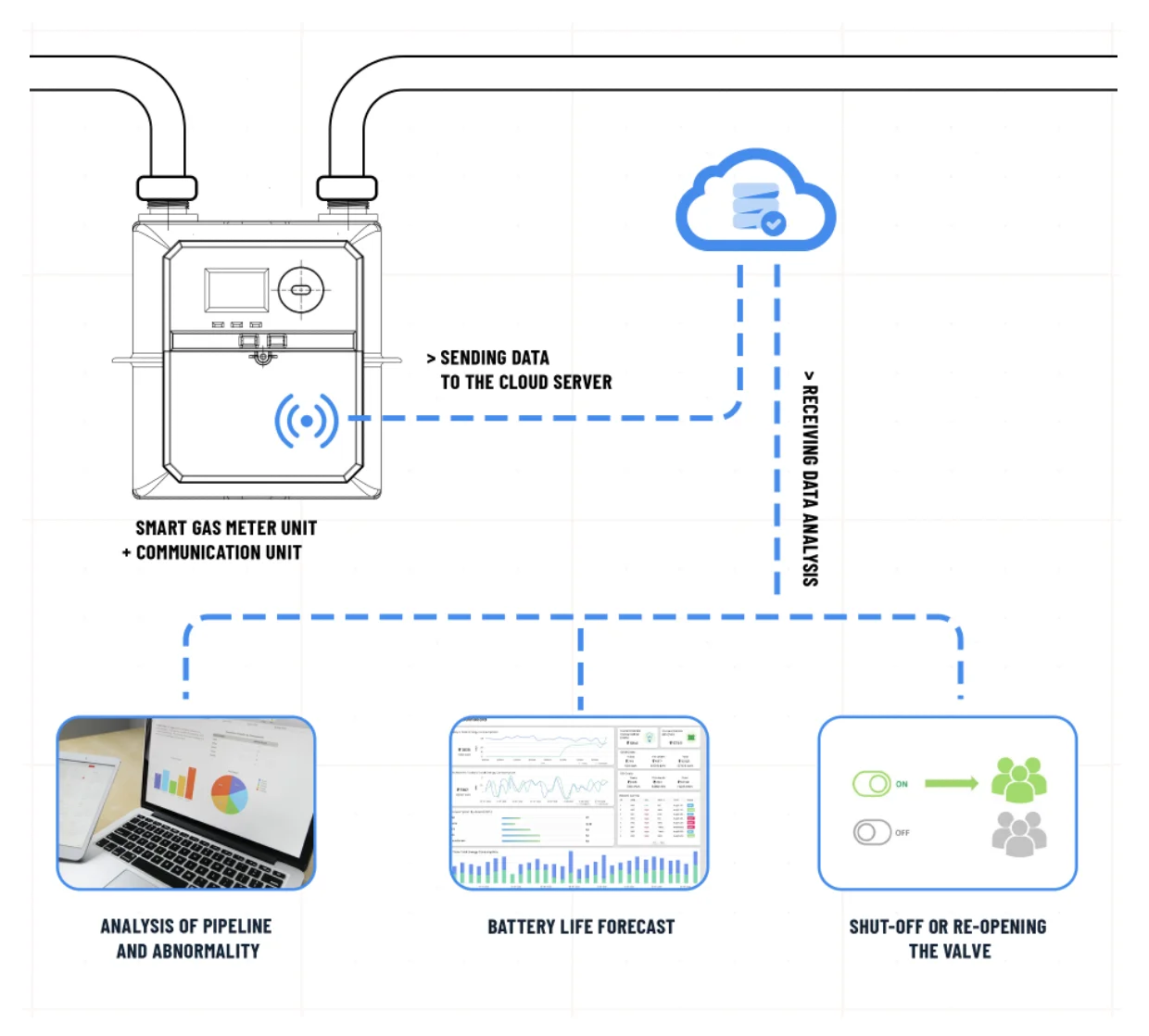

Figure 1-1: Smart Gas Meter NB-IoT System Architecture Overview

1.2 Components & Functions

Ultrasonic Smart Gas Meter

Uses ultrasonic time-of-flight measurement with no mechanical moving parts, accuracy up to ±0.5%, service life up to 20 years, supports bidirectional metering.

Diaphragm Smart Gas Meter

Traditional diaphragm metering + smart module, accuracy ±1.5%, lower cost, suitable for large-scale deployment, supports NB-IoT/LoRaWAN communication.

Industrial & Commercial Smart Gas Meter

High-flow turbine/rotary gas meters with temperature and pressure compensation, accuracy ±1.0%, suitable for industrial users and commercial buildings.

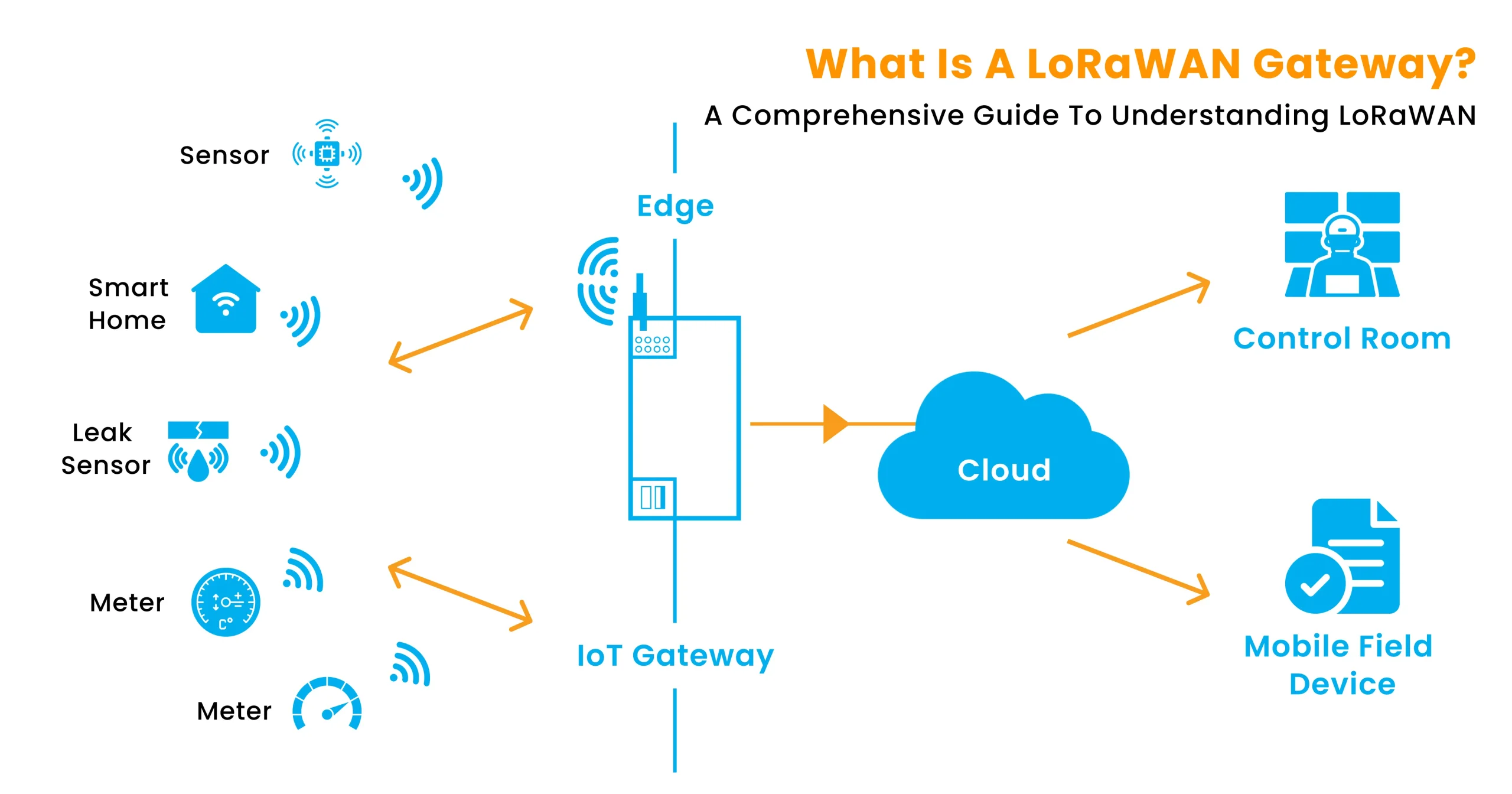

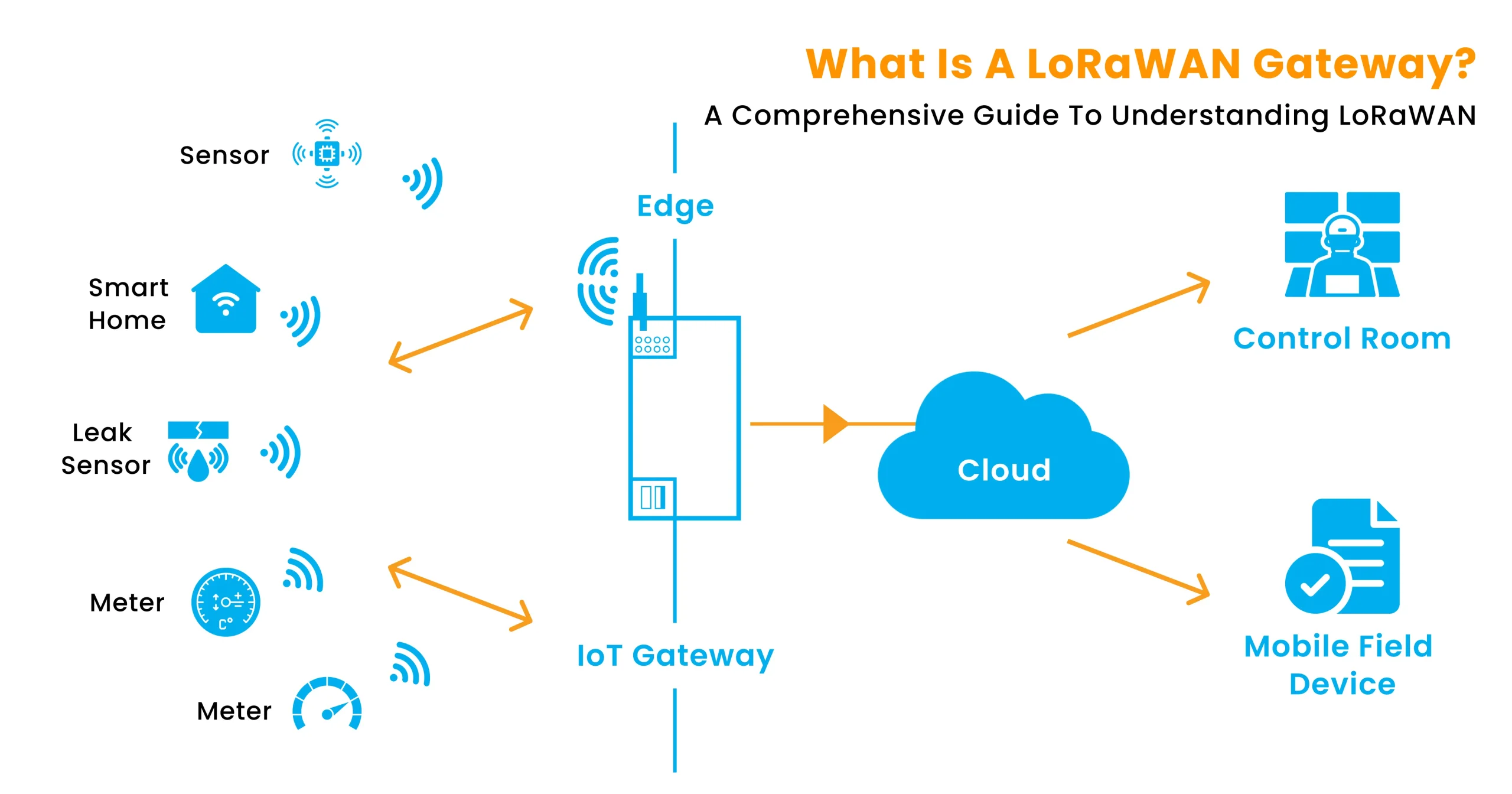

Communication Gateway/Concentrator

Supports LoRaWAN/NB-IoT protocol conversion, single gateway can connect thousands of gas meters, with local data caching capability.

1.3 Working Principles

Gas Metering

Smart gas meters measure gas flow in real-time using ultrasonic or diaphragm metering technology, storing data locally at set intervals (typically 15 minutes to 1 hour), while monitoring pipeline pressure and temperature.

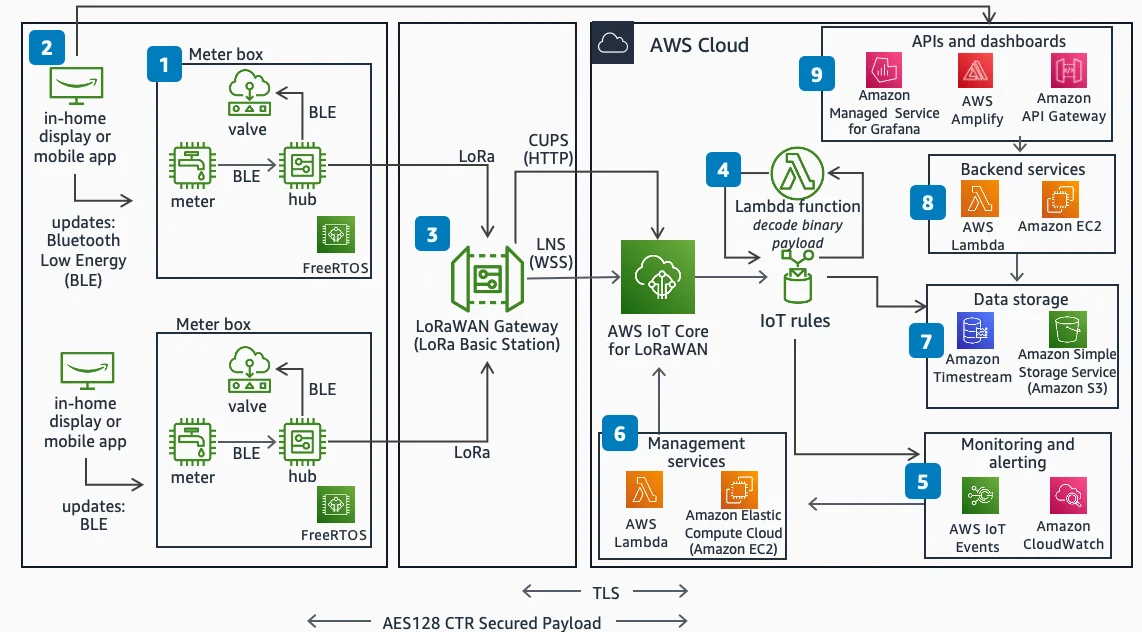

Data Transmission

Gas meters transmit metering data, status information and alarm data to the nearest base station or gateway via low-power wide-area networks such as NB-IoT/LoRaWAN, using AES-128 encryption to ensure data security.

Data Aggregation

Gateways/concentrators aggregate data from multiple gas meters and transmit it to cloud data centers via backbone networks such as 4G/fiber, supporting offline data buffering and data integrity verification.

Data Processing

MDMS (Meter Data Management System) validates, estimates, edits and stores data, generating billing data, gas usage analysis reports and anomaly alerts.

Safety Control

When the system detects leaks, abnormal gas usage or arrears, it can remotely issue valve closure commands, and the gas meter executes valve shut-off operations to ensure gas safety.

Design Guidelines

Core principles, standards and key consideration dimensions for smart gas meter system design

2.1 Design Principles & Standards

Safety First

Gas systems must meet explosion-proof requirements, using intrinsically safe circuit design to ensure no gas explosions occur under any fault conditions.

MeteringAccuracyConfirm

Gas MeterAccuracyShouldMeetTradeSettlementneedrequirement,ResidentialUser±1.5%,Industrial/CommercialUser±1.0%,SupportsT&P Compensation。

LongLifespanDesign

Gas MeterBattery LifeShould≥10years,MeteringMovementLifespan≥20years,ReduceReplacementMaintenanceProtectionCost。

Scalability

System ArchitectureSupportsFromThousandsToMillionsGas MeterlevelSmoothExpand,CommunicationProtocolSupportsMultipleTypeTechnologyCoexist。

2.2 Design GuidelinesHeavyneedPropertyandRecommendation

SmartGas MeterSystemDesignRequiredneedComprehensiveConsiderSafetyProperty、Reliability、EconomicPropertyandCanMaintenanceProtectionProperty。GasWorkAsFlammable and ExplosiveGasBody,SystemDesignMustMustWillSafetyPutAtFirst Priority,RequiredHasElectricalEquipmentMustMustMeetExplosion-proof Certificationneedrequirement。SameTime,ByatGas MeterThroughNormalInstallationAtHouseholdOutsideorPipeline Welletc.HarshEnvironment,EquipmentRequiredneedToolPrepareGoodGoodProtection RatingandEnvironmentSuitableShouldProperty。

2.3 CoreDesign/SelectTypeLogical

RequiredrequirementAnalysis

ClearConfirmUserRegulationMode、Gas UsageFeatures、SafetyneedrequirementandBudget Constraints

TechnologySelectType

SelectChooseMeteringTechnology(Ultrasonic/Diaphragm)andCommunication Technology(NB-IoT/LoRaWAN)

Solution Design

DesignNetworkTopology、DataFlowProcess、SafetyStrategyandEmergency Plan

ImplementVerification

DividePhaseDeploy、TestVerification、OptimizationCommissioningWhole

2.4 Key Consideration Dimensions

| Maintenancedegree | ConsiderneedPoint | RecommendationPointStandard |

|---|---|---|

| Performance & Experience | Metering Accuracy、ResponseSpeeddegree、Data CollectionCentralizedSuccess Rate | Accuracy±1.5%,CollectionCentralizedSuccess Rate≥99% |

| Stability/Reliability | EquipmentFailure Rate、CommunicationStability、DataCompleteProperty | yearsFailure Rate<0.5%,DataCompleteRate≥99.9% |

| Maintainability/Replaceability | RemoteDiagnosis、ModuleizationDesign、Spare parts commonality | SupportsOTARiseLevel,CommunicationModuleCanReplacement |

| Compatibility/Scalability | ProtocolStandardization、MultipleFactoryBusinessMutualOperation、CapacityExpand | SupportsDLMS/COSEMProtocol,APIOpenPut |

| GenerateLifePeriodCost(LCC) | ProcurementCost、InstallationCost、OperationMaintenanceCost、ReplacementCost | 10yearsTCOOptimal,Battery Life≥10years |

| Energy/Environment | EquipmentPower Consumption、BatteryTypeType、Material RingGuaranteeProperty | WaitMachinePower Consumption<10μA,LithiumBatteryCanRecycle |

| SafetyCompliance | Explosion-proof Certification、Metering Certification、Network Security | Ex ia IIC T4Explosion-proof Certification,MIDMetering Certification |

Application Scenarios

IntroductionSmartGas MeterSystemScope of ApplicationandClassicTypeApplication Scenarios

3.1 Scope of Application

SmartGas MeterSystemWidelyApplicableatRequiredneedperformGas MeteringandManagementVariousTypeScenario,IncludingButNotLimitat:Residential Communities、Commercial Complexes、Industrial Parks、Public Building、Gas Pipeline Networksetc.。SystemCanBased OnNotSameScenarioFeaturesperformFixedControlizationConfiguration,MeetMultipleSampleizationBusinessRequiredrequirement。

3.2 Typical Scenarios

Residential Communities

Business Characteristics

UserQuantityLarge、Gas UsageVolumeFluctuationObvious、BillingPeriodFixed(monthsdegree),RequiredSupportsPrepaidandTiered Gas Pricing。

Environmental Constraints

Gas MeterDivideScatterInstallationatKitchenorPipeline Well,SignalPenetrateneedrequirementHigh,RequiredConsiderPreventionWaterPreventionMoisture。

KeyRisk Points

EnterHouseholdInstallationCoordinateCommissioningDifficultdegreeLarge、Signal CoverageBlind Spots、UserPrivacyGuaranteeProtection、Meter ReadingDataDisputeProcessing。

Industrial Parks

Business Characteristics

Gas UsageVolumeLargeAndStable、RequiredneedDivideTimeMetering、MultipleFeeRateSettlement、PowerCauseNumberAssessment,RequiredrequirementSideResponse。

Environmental Constraints

ElectricMagneticInterferenceStrong、EnvironmentTemperaturedegreeChangeLarge,CanAbleStoreAtCorrosionPropertyGasBody,RequiredIndustrialLevelPreventionProtection。

KeyRisk Points

High FlowMetering Accuracy、T&P CompensationAccuracy、GenerateProductContinuousPropertyGuaranteeFailure、Energy ConsumptionDataSafety。

Commercial Complexes

Business Characteristics

TenantPublicMultiple、DivideHouseholdMeteringComplex、RequiredSupportsMultiple Billing Modes、Energy AnalysisRequiredrequirementStrong。

Environmental Constraints

Building StructureComplex、Frequent Renovation Changes、RequiredBeautifulObserveConcealedInstallation,NotImpactCommercialEnvironment。

KeyRisk Points

TenantChangeMoreTimeMeterServiceProcessing、PublicAreaDomainEnergy ConsumptionDivideShare、SystemandPropertyManagementCentralizedbecome。

Healthcare Facilities

Business Characteristics

UseAbleContinuousPropertyneedrequirementCritical、Department Independent Accounting、SpecialAreaDomain(Operating Room、ICU)RequiredHeavyPointMonitoring。

Environmental Constraints

ElectricMagneticCompatibleneedrequirementHigh、DisinfectionEnvironmentneedrequirementHigh、NoBacteriaAreaDomainLimitEnter。

KeyRisk Points

SystemFaultImpactMedicalSafety、DataPrivacyCompliance、UrgentSituationDownSupplyGasGuaranteeFailure。

Educational Institutions

Business Characteristics

UseAbleSeasonSectionPropertyObvious、DormitoryAreaRequiredPrepaid Management、LaboratorySpecialGas UsageRequiredrequirement、SectionAbleAssessmentPressure。

Environmental Constraints

CampusAreaLarge、BuildingDivideScatter、LearnGenerateDormitoryDenseCentralized、RequiredConsiderSafetyEducation。

KeyRisk Points

LearnGenerateViolateRegulationGas Usage、FalsePeriodEmptyPlacePeriodManagement、LaboratorySafety Monitoring、Energy ConsumptionDataPublicize。

Hotels & Hospitality

Business Characteristics

CustomerRoom IndependentMetering、andPMSSystemCentralizedbecome、Real-timeUseAbleMonitoring、SectionAbleManagementRequiredrequirement。

Environmental Constraints

Renovation GradeTimesneedrequirementHigh、EquipmentRequiredConcealedInstallation、NotImpactCustomerHouseholdBodyVerify、MaintenanceProtectionTimeBetweenWindowLimited。

KeyRisk Points

SystemandHotelManagementSystemCentralizedbecomeStability、CustomerHouseholdComplaintProcessing、Energy ConsumptionAbnormalFastSpeedResponse。

Gas Pipeline Networks

Business Characteristics

Pipeline NetworkDivideAreaMetering(DMA)、Leak Detection、PressureMonitoring、Production and SalesDifferenceAnalysis。

Environmental Constraints

UndergroundInstallationEnvironmentHumid、Manhole CoverDownSignalWeak、RequiredWaterproof and Corrosion-resistantDesign、MaintenanceProtectionCanReachPropertyDifference。

KeyRisk Points

UndergroundSignal Coverage、EquipmentPreventionWateretc.Level、BatteryReplacementPeriod、Pipeline NetworkLeakEarly WarningAccuracy。

GasCommissioningPressure Station

Business Characteristics

Safety MonitoringPriority、PressureFlowReal-timeMonitoring、RemoteCommissioningControl、EmergencyCutoff。

Environmental Constraints

Explosion-proofneedrequirementStrict、RequiredThisQualitySafetyDesign、HouseholdOutsideHarshEnvironment、Lightning StrikeRiskHigh。

KeyRisk Points

SystemFaultImpactSupplyGasSafety、Explosion-proof CertificationCompliance、ThunderElectricSurgePreventionProtection、EmergencyResponseTimeEffect。

Solution Selection

SmartGas MeterTechnical Solution ComparisonandSelectTypeDecisionPointSouth

4.1 MeteringTechnologyforCompare

| TechnologyTypeType | MeteringOriginalManagement | Accuracy | Lifespan | Cost | Applicable Scenarios |

|---|---|---|---|---|---|

| DiaphragmGas Meter | VolumeStyleMetering,GasBodyPush Diaphragm | ±1.5% | 10-15years | Low | Residential users, low flow |

| Ultrasonic Gas Meter | Time-of-flight gas velocity measurement | ±0.5% | 20years+ | High | High-end residential, commercial users |

| Turbine Gas Meter | Turbine speed proportional to flow | ±1.0% | 15years | Medium | Industrial/commercial, medium-high flow |

| Rotary Gas Meter | Positive displacement, rotary lobe metering | ±1.0% | 15years | Medium-High | Industrial users, high flow |

4.2 Communication Technology Comparison

NB-IoT

Advantages:Wide carrier network coverage, strong deep coverage capability, low power consumption, high security

Disadvantages:Requires SIM card and data fees, dependent on carrier network, limited downlink bandwidth

Applicable:Urban Residential、DivideScatterDeploy、NoRequiredSelf-builtNetwork

LoRaWAN

Advantages:Self-built network controllable, no data fees, long transmission distance, extremely low power consumption

Disadvantages:Requires gateway deployment, spectrum management, complex network planning

Applicable:ParkArea、Factory、CentralizedMediumDeployScenario

4G/5G

Advantages:High bandwidth, strong real-time capability, supports video monitoring

Disadvantages:High power consumption, high data fees, difficult battery power supply

Applicable:Industrial/CommercialLargeMeter、CommissioningPressure Station、RequiredReal-timeMonitoringScenario

4.3 Selection Decision Matrix

| Scenario | Recommended Meter Type | Recommended Communication | Key Considerations |

|---|---|---|---|

| Urban Residential | Diaphragm Smart Gas Meter | NB-IoT | Cost, Coverage, Battery Life |

| High-end Residential | Ultrasonic Smart Gas Meter | NB-IoT | Accuracy, Lifespan, Quiet operation |

| Industrial Parks | Turbine/Rotary Gas Meter | LoRaWAN+4G | Accuracy, T&P compensation, Real-time |

| Commercial Complexes | Ultrasonic/Diaphragm | LoRaWAN | Sub-metering, Centralized management |

| Gas Pipeline Networks | Ultrasonic Flowmeter | NB-IoT/4G | Accuracy, Protection rating, Reliability |

4.4 MainFlowFactoryBusinessProduct

Honeywell Q.Sonic

IndustrialLevelUltrasonic Gas Meter,Accuracy±0.5%,SupportsT&P Compensation,ApplicableatHigh FlowIndustrial/CommercialScenario。

Itron Smart Gas Meter

Residential-grade diaphragm smart gas meter, integrated NB-IoT communication, 15-year battery life, supports remote valve control.

Pulse Output Gas Meter

Traditional gas meter + pulse module, low-cost retrofit solution, suitable for smart upgrade of existing gas meters.

NFC/GPRS Smart Gas Meter

Supports NFC near-field communication for on-site commissioning and data reading, GPRS remote transmission.

Solution Design

Introduction to typical interfaces, device connections and wiring logic

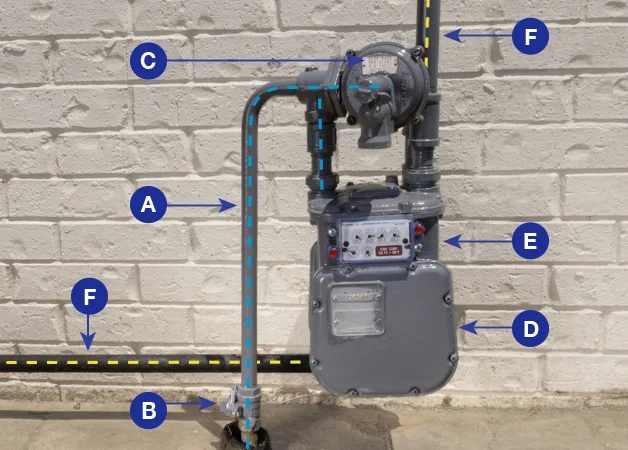

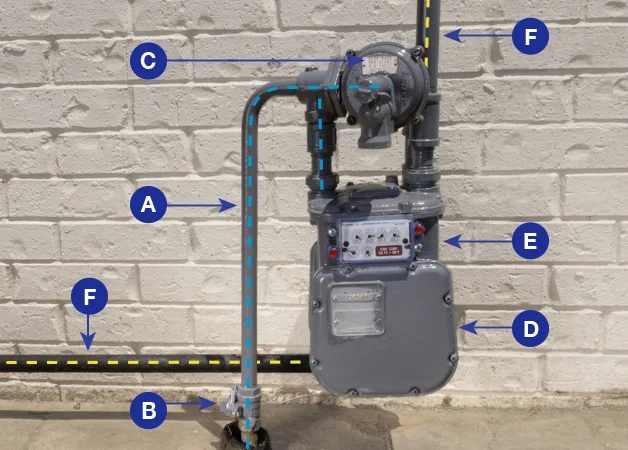

5.1 Typical Interface Introduction

Pulse Output Interface

Reed switch or Hall sensor output, each pulse represents a fixed gas volume (e.g., 0.01m³), used for external acquisition modules.

NB-IoT Communication Interface

Built-in NB-IoT module, supports Band 3/5/8/20 frequencies, directly connects to cloud platform via carrier network.

LoRaWAN Communication Interface

Supports Class A/B/C modes, operating frequency 868/915MHz, transmission distance up to 15km (open area).

Valve Control Interface

Built-in solenoid or motor valve, supports remote on/off control, with manual valve opening function and valve status feedback.

5.2 Device Connection & Interface Design

Figure 5-1: Smart Gas Meter System Device Connection Architecture

5.3 Typical Wiring and Interface Logic Description

Pulse Acquisition Wiring

Interface Type: Reed switch/Hall sensor

Cable Specification: RVVP 2×0.5mm² shielded cable

Maximum Distance: 50m

Notes: Single-end grounding of shield, avoid parallel routing with power cables

Valve Control Wiring

Interface Type: Solenoid/Motor valve

Cable Specification: RVV 4×0.75mm²

Power Requirements: DC 3.6V (battery) or DC 12V (external power)

Notes: Valve must have explosion-proof certification, wiring must meet intrinsic safety requirements

Gateway/Concentrator Wiring

Uplink Interface: RJ45 Ethernet/4G SIM card

Downlink Interface: LoRaWAN wireless/RS485 wired

Power Requirements: AC 220V or DC 12V

Notes: Antenna installation height ≥3m, avoid metal obstruction

5.4 Connection Specifications Description

| Connection Type | Interface Standard | Cable Specification | Maximum Distance | Precautions |

|---|---|---|---|---|

| Gas Meter-Collector | Pulse/RS485 | RVVP 2×0.5mm² | 50m/1200m | Requires 120Ω termination resistor |

| Collector-Gateway | LoRaWAN/NB-IoT | Wireless | 2-15km | Note antenna installation position |

| Gateway-Server | Ethernet/4G | CAT6/SIM card | Unlimited | Recommend dual-link redundancy |

| Valve Control | Dry contact/OC output | RVV 4×0.75mm² | 30m | Note explosion-proof rating requirements |

Risk Assessment

Risk identification, assessment and response strategies for smart gas meter systems

6.1 Risk Categories

Safety Risks

- Gas leak not detected in time

- Valve malfunction causing gas cutoff

- Explosion-proof equipment failure

- Electrical fire risk

Technical Risks

- Communication network failure

- Metering accuracy deviation

- Software system vulnerabilities

- Equipment compatibility issues

Cybersecurity Risks

- Data transmission eavesdropping

- System malicious attacks

- Valve illegal control

- User privacy breach

6.2 Risk Assessment Matrix

Risk Level Assessment

| Risk Item | Probability | Impact Level | Risk Level | Response Priority |

|---|---|---|---|---|

| Gas leak detection failure | Low | Critical | Severe | Highest |

| ValveRemoteControlLoseEffect | Medium | High | High | High |

| CommunicationNetworkMediumBreak | Medium | Medium | Medium | Medium |

| MeteringDataBiasDifference | Low | Medium | Low | Low |

| Network SecurityAttack | Low | High | High | High |

6.3 RiskResponse Strategies

AvoidStrategy

SelectUseAfterExplosion-proof CertificationEquipment,Strictly FollowThisQualitySafetyDesignSpecifications,FromSourceEliminate at SourceSafetyHidden Hazards。

MitigateStrategy

DeployRedundancyCommunicationLink,ImplementEndToEndEncryption,RegularSafetyAudit,ReduceLowRiskProbabilityandImpact。

TransferStrategy

PurchaseEquipmentResponsibilityRiskandNetwork SecurityRisk,andProfessionalSafetyServiceBusiness Cooperation,TransferPartialRiskResponsibility。

AcceptStrategy

foratLowGeneralRateLowImpactRisk,EstablishMonitoringMachineControlandEmergency Plan,AcceptResidualRisk。

6.4 Emergency Measures

Gas LeakEmergency

SystemDetectedLeakSignalAfter,AutomaticTriggerCloseValveCommand,SameTimeTowardUserandGasCompanySendAlarmNotification。On-site PersonnelShouldEvacuate Immediately,ProhibitedUseOpen FlameandElectricalSwitch,etc.WaitProfessionalPersonnel HandlePlace。

SystemFaultEmergency

MainSystemFaultTime,EdgeInsulationGatewayAutomaticSwitchToThisGroundModeStyle,ContinueExecuteRowData CollectionCentralizedandSafety Monitoring。SameTimeStartPrepareUseCommunicationLink,NotificationOperationMaintenancePersonnelperformFaultTroubleshoot。

Network attackEmergency

DetectedAbnormalVisitorAttackRowAsTime,SystemAutomaticIsolatedReceiveImpactNode,CutoffOutsideVisit,StartSafetyAuditandTraceSourceAnalysis,MustneedTimeNotificationNetwork SecurityDepartment Intervention。

Supporting Systems

SmartGas MeterSystemSupporting Hardware and SoftwareSystemIntroduction

7.1 Supporting SystemsOverview

SmartGas MeterSystemNormalOperationRowRequiredneedMultiplepcsSupporting SystemsSupport,IncludingData Management System、Cloud Platform、SupplyElectricSystem、NetworkBasicFacilitiesetc.。TheseSupporting SystemsCommonSameStructurebecomeCompleteSmartGas MeteringResolveSolution。

MDMSData Management System

Meter Data Management System,NegativeResponsibleGas MeterData CollectionCentralized、Verification、Storage、AnalysisandReportGeneratebecome,YesSystemCoreData Processinglevelunits。

CloudCalculatelevelunits

ProvideSupplyElasticPropertyCalculate、StorageandNetworkResourceSource,SupportsSystemHighCanUseDeployandElasticPropertyExpand,EnsureBusiness Continuity。

UPS Uninterruptible Power Supply

AsGateway、ServiceDeviceetc.KeyEquipmentProvideSupplyNotBetweenBreakSupplyElectricGuaranteeFailure,EnsureSystemAtCityElectricFaultTimeStillAbleNormalOperationRow。

NetworkBasicFacilities

IncludingLoRaWANGateway、NB-IoTBaseStation、RouteDevice、ExchangeMachineetc.,BuildCanRelyData TransmissionNetwork。

7.2 MDMS SystemFunction

| FunctionModule | Key Features | BusinessPriceValue |

|---|---|---|

| Data CollectionCentralized | MultipleProtocolAccess、FixedTime/Real-timeCollectionCentralized、BreakPointResume Transmission | EnsureDataCompletePropertyandAndTimeProperty |

| DataVerification | VEE(Verification、Estimate、Edit)Processing | GuaranteeCertificateBillingDataAccuracy |

| BillingManagement | Tiered Gas Pricing、Prepaid、AccountSingleGeneratebecome | SupportsMultiple Billing Modes |

| Safety Monitoring | Leak Detection、AbnormalGas Usage、Valve Control | GuaranteeFailureGas UsageSafety |

| ReportAnalysis | Gas UsageStatistics、Energy Analysis、PredictionReport | SupportsOperationBusiness Decision |

7.3 SystemCentralizedbecomeInterface

SmartGas MeterSystemRequiredneedandGasCompanyItsOtherBusinessSystemperformCentralizedbecome,MainneedIncluding:

- Business RevenueFeeSystem:TransferBillingData,ReceivePayFeeInformation

- GISGroundManagementInformationSystem:Gas MeterPositionManagement,Pipeline NetworkCanViewization

- SCADACommissioningdegreeSystem:Pipeline NetworkPressureMonitoring,CommissioningdegreeLinkage

- CustomerHouseholdServiceSystem:Gas UsageQuery,ReportRepairSingle

- ERPEnterpriseResourceSourceSystem:AssetsManagement,ProcurementManagement

Tools & Materials

SmartGas MeterSystemInstallationCommissioningTestRequiredRequiredToolsandAuxiliary Materials

8.1 Installation Tools

Gas MeterInstallation ToolsKit

IncludingPipeWrench、Wrench、Sealing tape、Pressure gaugeetc.,forGas MeterMechanicalInstallationandPipe Connection。

Network Tester

forTestNB-IoT/LoRaWANSignal Strengthdegree、NetworkConnectThroughPropertyandData TransmissionQuality。

Gas Detector

ConvenientCarryStyleCanGasBodyInspectMeasureInstrument,forInstallationCommissioningTest ProcessMediumLeak DetectionandSafetyConfirm。

HandHoldCommissioningTest Terminal

SupportsNFC/RedOutsideCommunication,forGas MeterParametersConfiguration、DataReadandFaultDiagnosis。

8.2 Testing Equipment

| EquipmentName | Purpose | TechnologyParameters |

|---|---|---|

| StandardGasBodyFlowMeter | Gas MeterAccuracyVerification | Accuracy±0.2%,Range0.016-25m³/h |

| PressureVerificationInstrument | PressureSensingDeviceSchoolAccuracy | Accuracy±0.05%FS,Range0-1MPa |

| SignalAnalysisInstrument | WirelessSignalTest | Frequency Range9kHz-6GHz |

| Data CollectionCentralizedDevice | CommunicationProtocolTest | SupportsDLMS/COSEM、Modbusetc. |

8.3 Auxiliary Materials

Sealing Materials

Specification:PTFEGenerateTape、Anaerobic Adhesive

Purpose:PipelineThreadConnectionSeal

LineCable Material

Specification:RVVPShieldingLine、RVVElectricSourceLine

Purpose:SignalTransmissionandSupplyElectricConnection

InstallationAccessories

Specification:Meter Box、Bracket、Connector、Snap

Purpose:Gas MeterFixedandGuaranteeProtection

8.4 ToolsList

| TypeOther | ToolsName | Quantity | PrepareNote |

|---|---|---|---|

| ThroughUseTools | Pipe wrenches, adjustable wrenches、Screwdriver Kit | Various1Set | Explosion-proofType |

| ElectricalTools | Multimeter、StripLineWrench、PressureLineWrench | Various1pcs | AbsoluteInsulationType |

| Testing Tools | Gas Detector、SignalTestInstrument | Various1units | RequiredRegular calibration |

| SafetyInstallPrepare | SafetyCap、AbsoluteInsulationHandSet、PreventionProtectionGlasses | AccordingPersonNumber | MustPrepare |

Quality Control

SmartGas MeterProduct Quality DifferentiationandQuality Control Measures

9.1 Product Quality Differentiation

SafetyAuthentication

| AuthenticationItemProject | Premium Products | Standard Products |

|---|---|---|

| Explosion-proof Certification | Ex ia IIC T4 | NoorEx ia IIB |

| Metering Certification | MID/OIML | OnlyThisGroundAuthentication |

| Network Security | ISO 27001 | NoAuthentication |

HardPieceProductQuality

| PointStandard | Premium Products | Standard Products |

|---|---|---|

| MCUChip | IndustrialLevel(-40~85°C) | CommercialLevel(0~70°C) |

| Battery | Lithium Thionyl Chloride | CommonThroughLithiumBattery |

| Protection Rating | IP68 | IP54 |

9.2 Potential Problems & Risks of Poor Quality

SafetyHidden Hazards

NotThroughExplosion-proof CertificationEquipmentCanAbleAtGasEnvironmentMediumProductGenerateElectricSpark,Cause Explosion Accident。ValveQualityNotQualifiedCanAbleCausingCloseValveNotStrictorNoMethodOpenStart,ImpactGas UsageSafety。

Metering Deviation

LowQualityMeteringMovementAccuracyDifference、TemperatureDriftLarge,CausingMeteringDataNotAccuracyConfirm,CauseUserComplaintandEconomic Disputes。LongPeriodUseAfterAccuracyDeclineMoreAsObvious。

Battery LifeShort

LowQualityBattery CapacityVirtualStandard、Self-dischargeElectricRateHigh,ActualService LifeRemoteLowatStandardCalledValue,CausingFrequent ReplacementBattery,IncreaseOperationMaintenanceCost。

CommunicationUnstable

LowQualityCommunicationModuleSensitivedegreeDifference、Transmit PowerUnstable,CausingData CollectionCentralizedSuccess RateLow,ImpactSystemWholeBodyCanUseProperty。

9.3 Quality Control MeasuresandRecommended Practices

EnterFieldInspectVerify

EstablishStrictIncoming MaterialInspectVerifyControldegree,forEveryBatchTimesProductperformExtractInspect,IncludingOutsideObserveCheck、Function Test、AccuracyVerificationetc.。

Aging Test

forKeyEquipmentperformHighTemperatureAging Test,ScreenSelectEarlyPeriodLoseEffectProduct,EnsureFactoryProductReliability。

AuthenticationReview

PrioritySelectChooseThroughExplosion-proof Certification、Metering Certification、QualityBodySystemAuthenticationSupplyShouldBusinessandProduct。

TraceabilityManagement

EstablishProductTraceabilityBodySystem,RecordEveryunitsEquipmentGenerateProductBatchTimes、InstallationPosition、MaintenanceProtectionRecord,ConvenientatQualityProblem TraceSource。

Calculators

ProvideSupplySmartGas MeterSystemDesignRequiredRequiredVariousTypeCalculators

10.1 System Capacity Calculation

CalculateSystemRequiredRequiredGatewayQuantityandServiceDeviceCapacity

Required Gateways:24 units

RecommendationServiceDeviceConfiguration:4Core8GB,200GBStorage

10.2 Link Redundancy Calculation

CalculateCommunicationLinkCanUsePropertyandRedundancyRequiredrequirement

RequiredRequiredRedundancyLinkNumber:2 links

Actual Availability:99.9975%

10.3 Network Performance Calculation

CalculateData TransmissionBandwidthRequiredrequirement

Peak Bandwidth Requirement:26.67 kbps

Daily Data Volume:45.78 MB

10.4 Power Requirement Calculation

CalculateSystemEquipmentElectricForceRequiredrequirementandUPSCapacity

Total Power Requirement:860 W

Recommended UPS Capacity:1118 VA

10.5 Battery Life Calculation

CalculateGas MeterBatteryExpectedService Life

Daily AveragePower Consumption:0.52 mAh

Estimated Battery Life:10.0 years

10.6 Coverage RangeCalculate

CalculateLoRaWANGatewayManagementTheoryCoverage Range

Link Budget:156.0 dB

Theoretical Coverage Radius:5.2 km

Installation & Commissioning

SmartGas MeterSystemInstallation Requirements、Construction StandardsandCommissioningTest MethodMethod

11.1 Pre-Installation Requirements

Site Survey Notes

- Confirm gas meter installation locationGasPipelineSpecificationandPressureetc.Level

- MeasureVolumeInstallationPositionNB-IoT/LoRaWANSignal Strengthdegree

- CheckWeekEdgeYesNoHasStrongElectricMagneticInterferenceSource

- ConfirmMeter BoxDimensionsandInstallationEmptyBetween

- RecordOn-siteEnvironmentTemperaturedegreeandWetdegreeRange

Risk PointsIdentify

- UndergroundPipeline WellSignal CoverageBlind Spots

- MetalMeter BoxforWirelessSignalShielding

- HighTemperature/LowTemperatureEnvironmentforEquipmentImpact

- HumidEnvironmentWaterproof and Corrosion-resistantneedrequirement

- Explosion-proofAreaDomainEquipmentSelectTypeneedrequirement

Essential Prerequisites

- GasPipelineAlreadyCompletebecomeInstallationandGas tightness test

- Meter Box/MeterPositionAlreadyInstallationCompleted

- CommunicationNetworkAlreadyDeployAndTestThrough

- AfterunitsSystemAlreadyUpLineAnd CompletebecomeConfiguration

- Construction PersonnelAlreadyCompletebecomeSafetyTraining

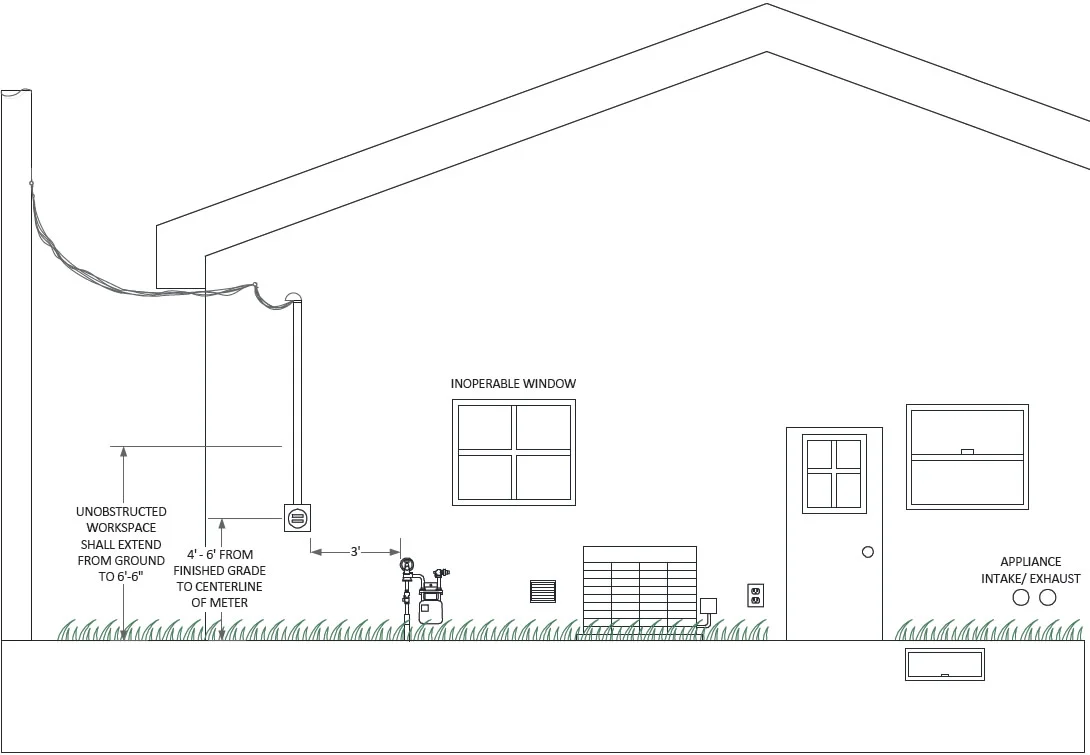

11.2 Installation Requirements

ResidentialGas MeterInstallation

InstallationHighdegree:MeterBottomDistanceGroundSurface1.4-1.8m

InstallationPosition:Good Ventilation,Easy access for meter reading and maintenance

SafetyDistance:DistanceElectricSourceSocket≥30cm

Meter Boxneedrequirement:NotMetalorOpenHoleMetalBoxBody

Industrial & Commercial Gas MeterInstallation

InstallationPosition:CommissioningPressureBox ExportorGas UsageEquipmentEntrance

BeforeAfterStraightPipeSection:Before10DAfter5D(DAsPipe Diameter)

T&P Compensation:RequiredInstallationTemperaturedegreeandPressureSensingDevice

Protection Rating:HouseholdOutsideInstallationRequiredIP65WithUp

11.3 Construction Standards

| ConstructionRingSection | Specificationsneedrequirement | Acceptance Standards |

|---|---|---|

| Pipe Connection | UseSpecialUseSealing Materials,ThreadConnectionRequiredWrapGenerateTape | Gas tightness testQualified,NoLeak |

| Gas MeterInstallation | WaterlevelInstallation,Import/Export PartyTowardPositiveConfirm,MeterDial FacingTowardConvenientatReading | InstallationFirm,NoTilt |

| daysLineInstallation | OutsidePlacedaysLineRequiredLead OutMeter Box,Avoid metal obstruction | Signal Strengthdegree≥-100dBm |

| LineCable Laying | ThroughPipeGuaranteeProtection,andGasPipelineGuaranteeHoldSafetyDistance | LineCableNoDamaged,ConnectorFirm |

11.4 Commissioning Methods & Precautions

ThroughElectricCheck

ConfirmBatteryVoltageNormal(≥3.0V),LCDDisplayNormal,NoAbnormalAlarm。foratOutsideSupplyElectricEquipment,CheckElectricSourceConnectLinePositiveConfirm。

Communication Test

UseCommissioningTest TerminalorAfterunitsSystemInitiateCommunication Test,ConfirmGas MeterAbleNormalUpReportData,DownRowCommandAblePositiveConfirmExecuteRow。

MeteringVerification

UseStandardFlowMeterforGas MeterperformVerification,ConfirmMeteringErrorDifferenceWithin AllowedRangeInside(Residential±1.5%,Industrial/Commercial±1.0%)。

ValveTest

TestRemoteOpenValve/CloseValveFunction,ConfirmValve OperationNormal,StatusFeedbackPositiveConfirm。Note:TestBeforeRequiredConfirmDownTravelNoGas UsageEquipmentOperationRow。

Gas tightness test

UseInspectLeakInstrumentforRequiredHasConnectionPointperformLeak Detection,ConfirmNoGas Leak。ThisYesInstallationCommissioningTest MaximumAfterAlsoYesMostHeavyneedRingSection。

11.5 Safety & Prevention

Personal Safety

- Construction PersonnelMustMustAfterGasSafetyTraining

- OperationTimeWear protective equipment

- ProhibitedAtGas LeakEnvironmentMediumOperation

- GuaranteeHoldOperationAreaDomainGood Ventilation

Equipment Safety

- UseExplosion-proof CertificationElectricalEquipment

- Prohibited to CarryElectricOperationGasEquipment

- EquipmentConnectGroundGoodGood

- ThunderstormdaysGasStopHouseholdOutsideOperation

Network Security

- ModifyEquipmentDefault Password

- StartUseCommunicationEncryptionFunction

- LimitRemoteVisitPermission

- RegularUpdateFirmwareVersion

Acceptance & Maintenance

FixedMeaningItemProjectDeliveryStandard,AndEstablishLongEffectOperationMaintenanceMachineControl

12.1 Acceptance Standards & Test Items

| Test Item | Test Content | Pass Criteria | Test Method |

|---|---|---|---|

| Metering Accuracy Test | SimulateNotSameFlow/LoadlinksPieceDownMeteringErrorDifference | ErrorDifferenceWithin AllowedRangeInside(Based OnDeviceMeteretc.Level) | Standard MeterMethodforCompareTest |

| Communication Test | Continuous72hoursDataUpReportSuccess RateStatistics | Success Rate≥99% | levelunitsDataStatisticsAnalysis |

| Function Test | Remote Meter Reading、ValveControl、Alarmetc.FunctionVerification | RequiredHasFunctionNormalResponse | FunctionGraduallyItemTest |

| Pressure Test | SimulateHighPeakPeriodLargeVolumeEquipmentSameTimeUpReport | SystemNoObviousLatencyorPacket Loss | LoadTesting Tools |

| Safety Test | Gas tightness test、Vulnerability Scanning、PenetrationTest | NoLeak,NoHighDangerLeakHole | ProfessionalSafety TestTools |

12.2 Operation & Maintenance Requirements

Daily Inspection (Daily)

- CheckGatewayPointIndicator,Display ScreenYesNoNormal

- ViewSystemAlarm,ConfirmNoAbnormal Events

- CheckData CollectionCentralizedSuccess RateYesNoReachStandard

- CheckServiceDeviceMagneticDiskEmptyBetweenandCPULoad

Regular Maintenance (Monthly/Quarterly)

- Mechanical:CheckGas MeterConnectionYesNoLoose,CleanMeter Box

- Electrical:CheckConnectLineEndSubYesNoLoose,ClearManagementChassisInsideDust

- Data:ArchiveHistoricalLog,DataStorageIndexOptimization

- Safety:UpdateSafetyPatch,CheckCertificateDocumentHasEffectPeriod

12.3 Version History & Revision Notes

| Version | Revision Date | Revised By | Description |

|---|---|---|---|

| v1.0.0 | 2025-08-01 | SolutionMall Technical Department | Initial version release,Contains12pcsSectionAndCalculators |

| v1.0.1 | 2025-09-15 | SolutionMall Technical Department | UpdateSolution SelectionSection,IncreaseNB-IoTTechnologyforCompare |

| v1.1.0 | 2025-11-20 | SolutionMall Technical Department | NewIncreaseBattery LifeCalculators,OptimizationRisk Assessment Matrix |

| v1.2.0 | 2026-01-05 | SolutionMall Technical Department | ImproveApplication ScenariosDescription,UpdateSupporting SystemsInterfaceList |

Contact Us

For any questions or suggestions, please visit our official website:

www.solutionmall.com